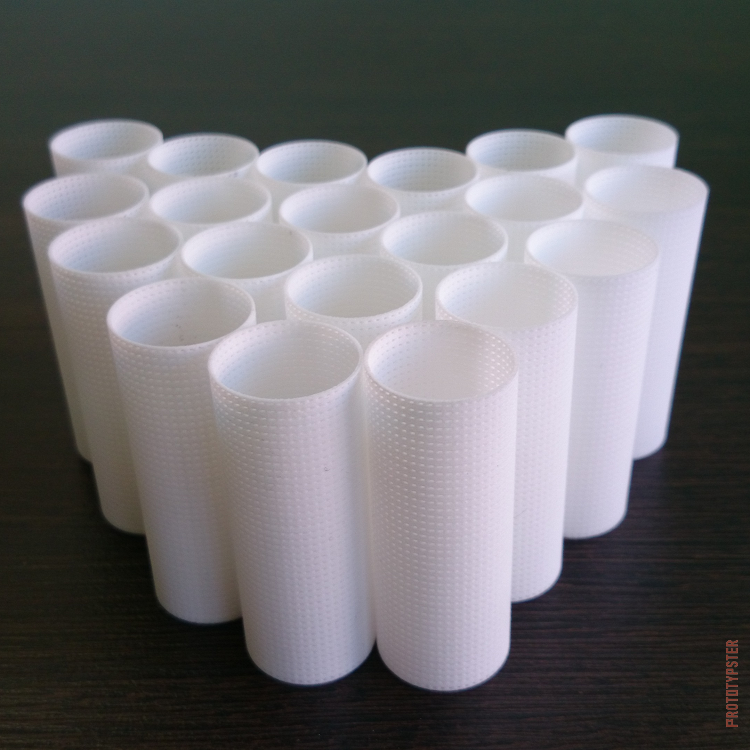

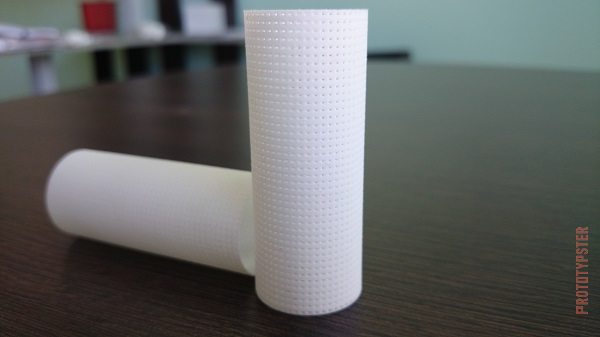

Many people believe 3D-printing is only useful for making decorate things. Prototypster breaks these stereotypes successfully. Among the many things we do for our clients, we make functional components and parts as well. One of Striking examples are filtering elements which today we are going to talk about.

"When you need to check the construction and ergonomics, 3D-printing is absolutely indispensable”, Arkadyi Kalina says, industrial and automotive designer, in an interview for Prototypster

The customer company engaged in printed circuit boards production. The solutions used for processing printed circuit boards must be free of any impurities. That is why special filters are widely used by the company in this kind of production.

There is a filtering element in every filter case. It allows having a right filtration. But this element tends to wear off while operated and needs to be replaced regularly. The filtering elements made by foreign manufacturers could be quite expensive while purchase and delivery process itself may take a long time.

Meanwhile these filtering elements can be easily manufactured here in Prototypster. 3D-printing of such polyamide items costs more than twice cheaper and ten times faster. By quality and characteristics finished filtering parts are as good as original ones – both in durability and wear resistance. Another advantage of additive manufacture is that the mesh size of the filter element can be easily changed in 3D-model before printing it.

If you have a unique mechanism, component or device, which is highly detailed and requires precise manufacture, it could be easily produced with the help of 3D-printing technologies. Please send us your orders, questions and offers to mail@prototypster.ru

Master-class: how to paint a polyamide figurine